Enhanced sustainability, greater efficiency

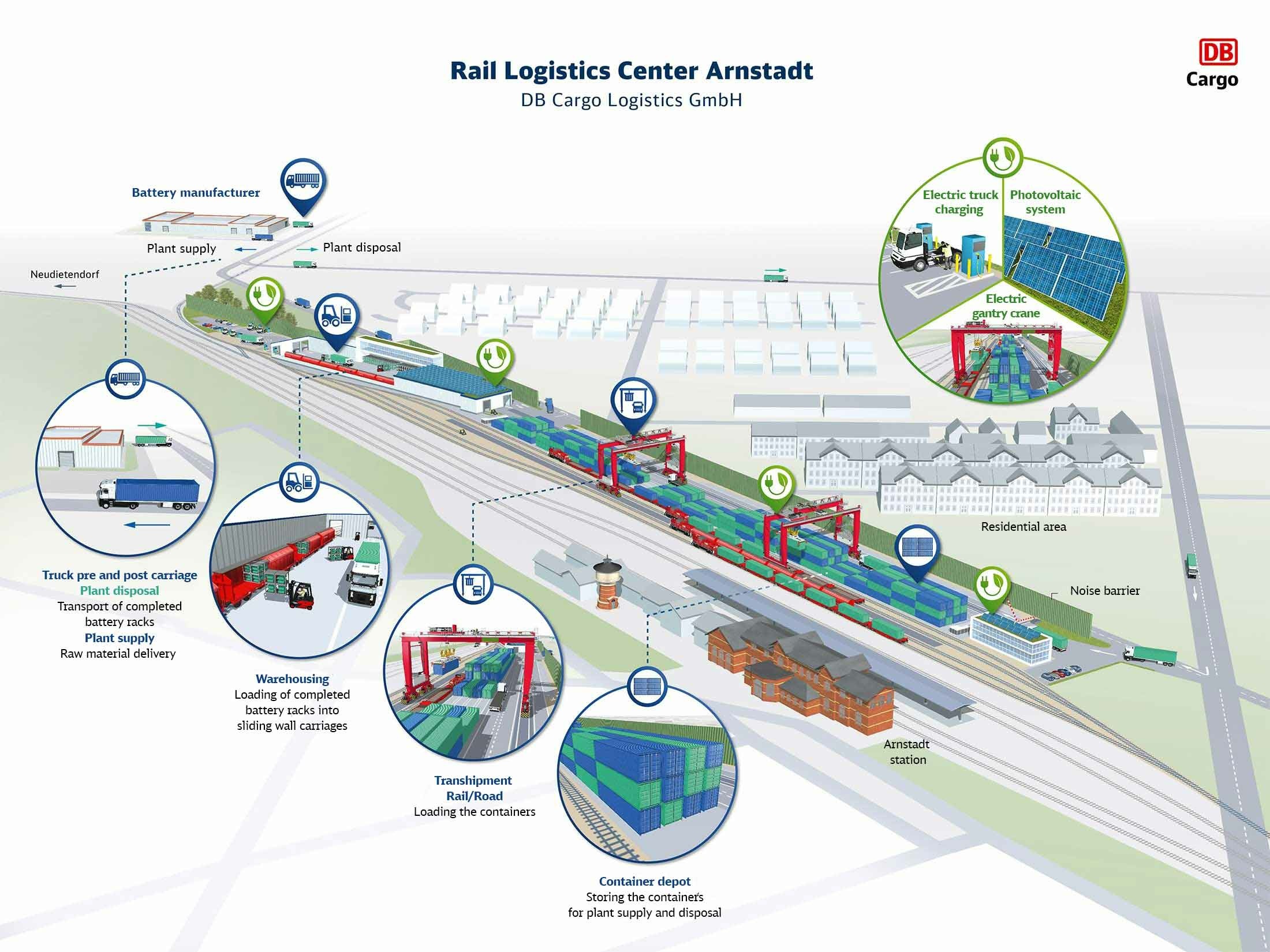

Efficient, innovative, sustainable and unobtrusive. These are the guiding principles for DB Cargo Logistics as we plan our new Rail Logistics Centre (RLC) at Arnstadt's former freight station. Weeds currently fill the site, but they are to give way to trains: up to four connections will load and unload at Arnstadt every day by the beginning of 2024.

The heart of Germany's e-mobility sector

The future RLC Arnstadt is located only a few kilometres from Erfurter Kreuz, Thuringia's largest industrial zone. A Chinese battery manufacturer is currently building one of Europe's largest battery cell plants here, while more and more companies move into adjacent sites. "Erfurter Kreuz is of interest to us at DB Cargo Logistics, not least because it currently lacks a link to the rail network," says project manager Jahn Reich. Kai Birnstein, head of the automotive team at DB Cargo Logistics, expands on this: "The shift to e-mobility is a key issue for the car industry. Our response is to develop the right rail logistics solutions so our customers can meet their future requirements. We are already putting the first generation of battery logistics solutions into action within our efficient network."

Picking up the pace with plug and play

Every day, over 250 trains are on the move for DB Cargo Logistics' Automotive RailNet. To avoid creating a brand new network of connections for every supplier, we have adopted what we call a "plug and play" approach to our planning activities at RLC Arnstadt. This entails connecting a new supplier to the existing Automotive RailNet system, a bit like how you plug in a USB stick. This new customer can then make use of the network more or less straight away and start supplying its own clients. Jahn Reich says, "This gives us a clear competitive advantage because we have a network that is set to the car sector's clock, something that benefits new suppliers from the get-go." Against this backdrop, we are planning to equip the terminal for both conventional rail freight and combined transport (CT) services. Reich says: "The hub will be different to the usual CT terminals and railports, which obviously gives us a unique selling point. RLC Arnstadt will combine the advantages of both types of terminal at a single site."

Renewable rooftop electricity

The issue of sustainability also plays a major role in the terminal's planning. For example, using electric tractor-trailers for last-mile links will make it possible to provide a transportation service that is completely CO2-free. The terminal's other facilities will also run purely on electricity so it can get as close as possible to the goal of being carbon neutral. This will apply to the site's gantry cranes (RTG cranes) as well as to the forklifts at the site. Photovoltaic systems on the roofs of the hub's buildings will supply the necessary electricity. "Under ideal conditions, we will be able to generate half a million kWh of our own renewable electricity every year. We plan to use this for our recharging needs and for powering equipment," explains project manager Reich.

In the name of neighbourliness

Minimising noise is another important goal. Some of the relevant measures include cladding for roof-mounted power units and use of the latest generation of rubber-tyre gantry cranes so operations are as silent as possible. Low-noise container transhipment is another option for keeping things quiet. Today's gantry crane systems are equipped with what is known as a "soft landing" feature. This function reduces the noise made when setting containers down, and it will minimise the impact this activity has on our surroundings. The same principle underpins operations planning for RLC Arnstadt. Jahn Reich explains that DB Cargo Logistics is designing a two-shift system with the goal of minimising potential disruption to life in the town. He says, "We want to blend in with the urban fabric. For this reason, issues like architecture and urban planning also play an important role in the planning process."

Leading the way in resilient supply chains

Despite time pressure and the wide range of objectives, Reich and his team have managed to tackle another challenging situation: the massive disruption that the pandemic repeatedly inflicts on some supply chain activities. "We can already tell that RLC Arnstadt will enable us to strengthen our customers' supply chains. Our operations will create a degree of slack in the system, which significantly increases the terminal's ability to cope with any changes in either inbound or outbound traffic. For example, we will be able to store containers for a certain duration when supplying customers at Erfurter Kreuz. Similarly, we be able to also absorb production surpluses if they occur. Combined, these will improve the responsiveness and resilience of our customers' supply chains."

Further information about Arnstadt's rail logistics centre is available at https://www.rlc-arnstadt.de/ (German only).